AI that augments the workforce … and doesn’t replace it

What you’ll learn:

- Manufacturers face a dual challenge: the shrinking labor pool, yes, but also the literal retirement of institutional knowledge.

- AI and machine learning will have the most impact among the leading technologies in the next five years. What’s important with AI are the use cases.

- There is no doubt that AI will lead to a remarkable job transformation in the industrial world in the next few years.

Editor’s note: This is the second part of a four-part series, the Smart Operations Playbook. In Part 1, Colin Masson made the case for "taming the data beast" by establishing industrial data fabrics. For Part 3, ARC's Patrick Arnold will tackle physical machines, exploring how intelligent robotics, powered by the industrial edge, are putting intelligence into motion on the factory floor.

Related content:

AI adoptions help push monthly industrial job losses to 20-year high

A report by Challenger, Gray & Christmas has set the discussion about AI and its impact on the manufacturing workforce ablaze.

That outplacement firm’s data laid 153,074 job losses across industries in October mostly at the feet of “cost-cutting.” The second-leading cause, however: AI adoption.

AI was supposed to augment jobs, not replace the people who occupy them, correct? The Manufacturing Institute did tell us that 3.8 million new workers will be needed by 2033.

The first part of this series dealt with industrial data fabrics. Once you have that clean, contextualized data, what then? The answer is deployment of practical artificial intelligence.

But with AI often framed as a job-killer—as the Challenger, Gray & Christmas report would seem to suggest—and if people are needed on the factory floor so badly in the next decade, as The Manufacturing Institute said last year, how are we to establish AI’s place and purpose.

The reality, for industry, is nuanced.

Demystifying industrial AI

We’ll focus this article on industrial AI and its role as a powerful tool to augment and empower a shrinking, less-experienced workforce.

We’ll explore high-impact, practical AI applications delivering real ROI today—from predictive maintenance and asset performance management to AI-powered quality control.

The goal is not to automate people out of the process—but to amplify their impact.

The focus is on how AI acts as a "super-assistant," amplifying the expertise of existing workers and making manufacturing careers more attractive to a new generation.

Manufacturers face a dual challenge: the shrinking labor pool, yes, but also the literal retirement of institutional knowledge. People do not live—nor do they want to work—forever.

However, The Manufacturing Institute also reported that about 1.9 million of the 3.8 million jobs needed could quite possibly go unfilled if the skills gap persists in industry.

See also: Our annual State of Initiative Survey is open!

ARC Advisory Group’s research highlights that the solution is not to replace workers with machines; the answer is augmenting human capabilities with AI. AI won’t replace people—but people augmented with AI will replace people without AI.

Industrial AI offers a strategic response to this workforce crisis, enabling organizations to preserve expertise, automate routine tasks, and empower a new generation of human workers with intelligent tools.

Putting AI to work: Practical use cases

An AI model, simply put, is a system trained to recognize patterns in data and make predictions or decisions. In industrial contexts, models range from traditional machine learning to multimodal systems that combine sensor data, images, text, and diagrams.

ARC outlines the key data types used in industrial AI:

- Sensor data: Real-time measurements from equipment

- Process data: Historian logs, KPIs, batch records

- Asset data: Maintenance history, work orders

- Quality data: Inspection results, defect tracking

- Engineering drawings: CAD diagrams, schematics

- Text data: Operator logs, manuals, SOPs

- External data: Weather, market trends, supply chain info

These models are increasingly leveraged in industry and are now often embedded into industrial co-pilots and AI agents, enabling real-time decision-making, predictive maintenance, improved quality control, and better energy optimization.

According to a recent ARC survey, AI and machine learning will have the most impact among the leading technologies in the next five years. What’s important with AI are the use cases.

According to a recent ARC survey, AI and machine learning will have the most impact among the leading technologies in the next five years. We follow with some major use cases in industry for these technologies.

Predictive maintenance

While predictive maintenance (PdM) has been around for many years, earlier machine learning-based algorithms focused primarily on anomaly detection for predicting asset failures.

Today’s advanced AI—deep learning, knowledge graphs, and causal AI—go beyond this by integrating data from varied sources and analyzing it within different contexts, such as production environments, system conditions, and operational parameters. These innovations are making predictive maintenance smarter, more contextual, and increasingly autonomous.

Q&A: How analytics, AI, digital twins help manufacturers build resilient supply chains

Additionally, AI now supports adaptive learning. Previously, keeping ML-based PdM algorithms posed a major challenge for maintenance teams. With AI, models can continuously improve themselves as new data arrives and operating conditions change.

This capability enhances the effectiveness of AI-driven PdM and accelerates the shift from reactive to predictive maintenance.

Quality control

Machine vision systems powered by AI can detect defects with superhuman accuracy. Rather than depending on human inspectors or traditional rule-based vision systems, manufacturers are increasingly implementing AI-powered quality control.

Industrial AI offers a strategic response to this workforce crisis.

Traditional rule-based systems operate with fixed parameters and predefined defect templates, requiring manual programming by engineers. In contrast, AI-based systems are capable of autonomously learning from input data.

See also: Human intelligence plus AI and how supply chains are changing with this collaboration

AI-based advanced systems exhibit greater resilience to changes in lighting conditions and product variations and can even identify micro-defects that may be undetectable to both human inspectors and conventional rule-based solutions.

Moreover, sophisticated AI based systems can analyze the underlying causes of defects by correlating them with process parameters, operator actions, or substandard raw materials, thereby facilitating comprehensive root cause analysis and process optimization.

Energy optimization

AI models analyze plant-wide data, including sensor inputs, historian data, and external sources like weather forecasts—to optimize energy consumption. Manufacturers aiming to optimize energy typically rely on manual adjustments and static models. Although these approaches help cut down on some energy waste, these are not ideal due to constantly changing plant conditions.

See also: Survey: Data quality issues costing manufacturers billions

By comparison, AI-driven systems can continuously learn and automatically improve, providing real-time energy management across the entire facility. This leads to more sustainable operations and cost savings, especially when AI is deployed at the edge for low-latency decision-making.

The new role of the industrial workers

There is no doubt that AI will lead to a remarkable job transformation in the industrial world in the next few years. Maintenance technicians will no longer just be "parts-swappers."

Augmented by powerful AI tools, they will become data-driven “asset performance management experts.” Instead of fighting fires, they will be proactively able to manage the health of their assets to minimize unplanned downtime.

Operators will evolve into “AI team managers.” They will oversee operations where collaborative robots (cobots) perform repetitive and ergonomically demanding lifting tasks. The operators in the AI-age will be responsible for performing complex final assembly procedures and conducting quality assurance evaluations.

New hires will be “connected workers” from Day One. Instead of handing a new hire a 200-page paper manual, equip them with a tablet or AR glasses. An AI assistant, fed by the data fabric, can provide step-by-step digital work instructions, overlay safety warnings, or instantly connect them via video to a remote expert for help.

See also: Talking to your data: Agentic AI’s utility in process manufacturing

These digital tools will equip users with expertise comparable to that of a seasoned professional with decades of experience, significantly decreasing training duration and enhancing safety.

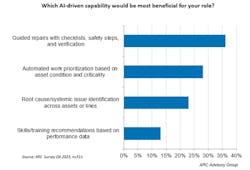

In a recent APM focused survey, industry participants highlighted that guided procedures and checklist capability would be most valuable to their role.

The symbiotic future of humans and AI

ARC envisions a symbiotic future where humans and AI collaborate to create safer, more productive, and engaging industrial environments. With the help of AI, industrial jobs are becoming more data-driven and tech-enabled, aligning with the expectations of younger workers. AI tools are making industrial roles more engaging by integrating intuitive interfaces and intelligent assistants.

By leveraging AI, manufacturers can overcome workforce challenges and unlock new levels of efficiency and innovation. Ultimately, the goal is not to automate people out of the process—but to amplify their impact. The future factory is not just smart; it's human-centric and AI-empowered.

About the Author

Craig Resnick

Craig Resnick is VP of consulting at ARC Advisory Group and is the primary analyst for many of ARC’s automation supplier and financial services clients. His focus areas include production management, OEE, HMI software, automation platforms, and embedded systems.

Inderpreet Shoker

Inderpreet Shoker is director of research for ARC Advisory Group and performs research and consults with clients in the areas of asset performance management, asset integrity management, plant asset management, and asset reliability. She also leads the research on augmented reality and other extended reality technologies at ARC.