Talking to your data: Agentic AI’s utility in process manufacturing

What you’ll learn:

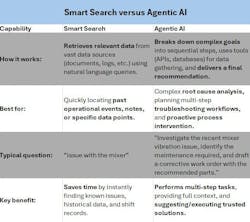

- Smart Search helps teams find the right information fast, even across years of unstructured records.

- Agentic builds on that foundation, enabling dynamic conversations with your data to surface insights, detect patterns, and recommend next steps.

- While Smart Search delivers fast answers to known questions, agentic expands that capability to support complex, dynamic decision-making.

If your plant could talk, what would it say?

Thanks to the latest advancements in AI, that question is no longer hypothetical. Manufacturers now have powerful new ways to interact with factory data—whether it's retrieving years of shift notes through Smart Search or engaging in real-time, natural-language conversations.

The newest frontier is agentic AI—AI systems that go beyond passive data retrieval to actively assist, interpret, and guide decision-making. Built on cutting-edge generative AI, agentic transforms how teams’ access and apply operational knowledge across the plant floor.

See also: From Bridgeports to cobots: How manufacturing tech changes challenge the depleted workforce

Smart Search helps teams find the right information fast, even across years of unstructured records. Agentic AI builds on that foundation, enabling dynamic conversations with your data to surface insights, detect patterns, and recommend next steps.

Used together, Smart Search and agentic AI empower manufacturers to navigate complexity, retrieving known data quickly while generating fresh insights for continuous improvement.

Smart Search: Fast answers when you know what you need

Smart Search is built for speed and precision. By indexing structured and unstructured data—from MES and logs to shift notes and maintenance records, this tool helps operators and engineers find exactly what they need, when they need it.

Unlike traditional keyword search, which relies on exact phrasing and structured data, Smart Search uses natural language processing to understand the intent behind a query.

See also: Turning workforce challenges into digital opportunities

That means operators can search using plain language and quickly find the information they need—even if they don’t know the exact terms or where the data is stored. Smart Search excels at:

- Real-time data access: Smart Search enables quick retrieval of relevant data from various sources, helping operators make informed decisions on the spot.

- Fault detection: It can efficiently search through historical data to identify patterns and detect faults in the production process.

- Supply chain management: Smart search can streamline the search for suppliers, materials and logistics information, optimizing the supply chain.

- Production planning: It helps find and organize data related to production schedules, inventory levels, and resource allocation.

With AI-powered Smart Search, users can quickly surface the information they need from large, diverse sets of structures and unstructured data, often reducing search times from hours to minutes.

While Smart Search delivers fast answers to known questions, agentic AI expands that capability to support complex, dynamic decision-making.

Q&A: Roadmap to Industry 5.0 with Ganesh Bukka of Hitachi Digital Services

Instead of retrieving existing entries, it allows users to “chat with their data”—asking complex open-ended questions and follow-up questions using natural language and getting intelligent, context-aware responses.

This makes it ideal for exploratory analysis and decision-making in uncertain or unfamiliar situations.

Potential agentic AI use cases include:

- Root cause analysis: An engineer asks, “Why are we seeing lower yield on Line 3 this week?” Agentic AI analyzes the operator context for similar situations in the past, highlights unusual temperature fluctuations recorded during those times, and suggests checking a specific sensor that was identified in prior similar scenarios, which speeds up finding possible root-causes.

- Dynamic troubleshooting guidance: An operator troubleshooting a mixing issue receives a step-by-step guide generated in real-time based on prior successful fixes, equipment conditions, and specific batch parameters, ensuring immediate, effective action.

- Process optimization: A manager asks, “What are three ways to reduce energy consumption in the dryer system?” Agentic AI pulls historical efficiency data, compares peak performance conditions, and offers actionable suggestions.

- Training and onboarding: A new hire queries, “How do we typically respond to a pressure drop in Reactor 2?” and receives a summary of historical issues, responses and outcomes—instantly transferring institutional knowledge.

- Operational issue detection: Agentic AI analyzes unstructured data from shift logs, maintenance notifications, and efficiency data) to surface early warnings of recurring operational issues, identifying precursors to failure that were previously hidden in text, and preventing minor issues from escalating into major unplanned events.

Agentic AI tools help manufacturers move from static recordkeeping to real-time, collaborative problem-solving.

By surfacing relevant historical events, highlighting likely causes, and offering step-by-step recommendations, these tools streamline investigations, accelerate resolution of production issues, and reduce the risk of recurring problems—all while minimizing downtime and avoiding costly batch or quality failures.

AI case study: Bayer Crop Science

Bayer Crop Science in Muttenz, Switzerland, was an early adopter of AI in plant operations.

In 2021, they integrated an AI-powered Smart Search system into their centralized plant process management platform. The goal: Make critical operational knowledge easier to access across shifts, teams and systems.

Smart Search dramatically reduced the time spent on troubleshooting, root-cause analysis and data gathering—from hours to minutes. Instead of sifting through years of shift notes or digging through maintenance logs, employees could ask questions in plain language and instantly retrieve the most relevant, context-specific insights.

See also: Skilled workforce should be the nation's first priority

Making Smart Search work required a strong digital foundation. That meant digitizing key activities (such as shift notes, maintenance logs and inspection observations) and implementing a centralized data management platform that could pull data from disparate systems such as the SAP and historian.

The AI system was trained and tuned to recognize Bayer’s unique plant workflows, terminology and data sources, making its responses both accurate and highly relevant. As a result, Bayer has been able to streamline operations, improve efficiency, and reduce the time it takes to identify, troubleshoot and respond to problems.

Agentic synergies via standardized protocols

Connecting agentic AI systems using common standards like model context protocol or agent-to-agent lets a central AI assistant pull data from different plant systems without hassle. With this smooth access to real-time information, the AI can handle complex tasks more quickly and accurately.

See also: With MFT use growing among manufacturers, new findings see critical cybersecurity gaps

That means teams get faster answers, better problem-solving, and can even automate entire workflows. And because the AI understands the plant’s specific setup and goals, its actions stay aligned with what matters most on the floor.

Getting started with AI in process manufacturing

For process manufacturers, unlocking the value of AI starts with building the right digital foundation. It’s not as simple as plugging in an off-the-shelf AI tool. Systems must be tailored to your operations, your plant and your people. That means taking a few key steps:

- Digitize key processes. Replace paper-based shift notes, maintenance logs and inspection rounds with structured digital records that can be captured, searched and shared in real time.

- Centralize your data. Use a PPM system to connect data from MES, LIMS, historians, QMS and human inputs, giving AI tools a comprehensive view of plant operations.

- Tune AI to your context. For AI to provide accurate, relevant insights, it must be trained on the specific language, workflows and processes of your industry and site. That’s what makes results actionable rather than generic.

AI tools like Smart Search and agentic AI are driving a shift from disconnected data to connected intelligence. Used well, AI empowers human workers, reduces downtime and unlocks the full potential of the smart factory.

Podcast: Why IT and OT remain out of sync and how manufacturers can bridge that gap

This shift is part of a broader evolution toward Industry 5.0, where intelligent technologies are designed not just for automation, but to augment human expertise and foster more resilient, people-centric operations.

When these pieces are in place, AI becomes an operational partner: amplifying human expertise, accelerating issue resolution and supporting smarter, faster decisions.

About the Author

Andreas Eschbach

Andreas Eschbach is the founder and CEO of global software company eschbach and invented plant process management platform Shiftconnector, which helps production teams streamline shift-to-shift communications and enables better data sharing and workforce collaboration. He has led a variety of international software initiatives for major process manufacturing companies, especially in chemical and pharmaceutical industries.