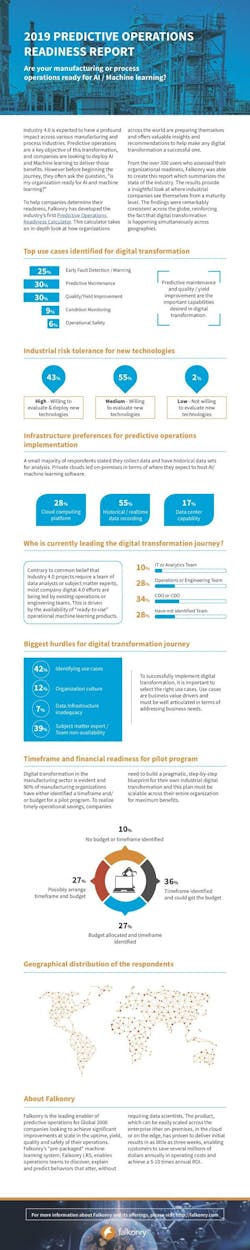

Predicting predictive-operations readiness

Are we ready for predictive operations? That sounds like a trick-questions, doesn’t it?

But that is at the heart of a recent study conducted by Falkonry that looked at machine

Falkonry's Sanket Amberkar

learning/predictive-operations readiness using an online readiness calculator. We wanted to learn more, so we connected with Sanket Amberkar, Falkonry SVP of marketing to explore the study, mass-adoptable technology and owning transformation problems. Take a look…

Smart Industry: What's new in predictive-operations readiness?

Sanket: Many Industry 4.0 and IIoT efforts get stuck in proof-of-concept and do not progress to production despite having strong business objectives and availability of sensors and data. This is often because the solutions and tools developed do not scale, or are difficult to use for operations teams. With predictive operations, the focus is on AI or machine-learning approaches that are “ready-to-use” by manufacturing and process engineers.

The readiness calculator then provides a holistic assessment across four key dimensions: business objectives, data infrastructure, budget & timeframe and team readiness. This helps identify if the right stakeholders are engaged and provide specific recommendations on next steps.

Sanket: 39% of respondents identified access to data scientists and subject-matter experts as the biggest challenge for their organization. For AI and machine learning, the democratization of data science has been the most important trend to help accelerate adoption. The ease of use of technology by end users has enabled them to develop and deploy predictive-analytics models themselves, without requiring assistance from data scientists. This is especially true in manufacturing and process industries where data-science resources are scarce or over-committed.

Smart Industry: Who do you think is driving digital transformation in the industrial space?

Sanket: Transformations are catalyzed by mass-adoptable technology. It is for this reason that, while innovation and analytics teams play a role in identifying and recommending new technologies, the actual digital transformation is being driven by COOs, CIOs, and operations/engineering teams who actually own the problem and are accountable for delivering against specific business-level objectives.

Smart Industry: What most surprised you in the findings of this study?

Sanket: Many organizations have invested significant time and talent to advance their Industry 4.0 initiatives. However, it was surprising to see that 42% of the companies still found it challenging to identify and prioritize use cases. While, intuitively, it would seem obvious to start with your most pressing problems, we’ve observed teams sometimes handicap themselves by assuming that sufficient operational data may not be available.

On the other hand, 43% of companies indicated a high willingness to evaluate and deploy new technologies, with only 2% being against. This shows an increasing culture innovation and risk tolerance for new projects.