Case Study: Analytical software predicts sewer-system blockages

Often the first notification of a spill comes from a member of the public, hours and sometimes days after the actual incident. Such late notice can intensify public-health and environmental impacts, and increase the cost of cleanup efforts.

Following a sewer spill at an environmentally significant site at Midway Point in Tasmania in August 2017, the statewide water utility sought a way to reduce the likelihood and impact of future spill events. They needed a way to predict future sewage spills, with plenty of notice so preventive measures could be taken.

The system has 970 water and sewage-pumping stations. A portion of these are high-risk sites where spills have occurred in the past. The system also has 176,000 sewer connections across the state, and suffers about 2,000 sewer mains breaks and spills per year.

Having previously worked with the utility on its process-historian data-management system, Nukon was asked to identify and provide a proof-of-concept for an online sewer-blockage detection system.

Analyzing the data

Using Seeq to analyze data from the process historian, we developed and tested a model based on data from the Midway Point spill event in August 2017. The goal was to see if the model could detect the blockage faster than current methods.

As we knew that Seeq enables engineers to get more value from data already collected, and enables organizations to access and execute on those insights, we partnered with them, determining that the best indicator of a blockage event [Figure 1] was in “The Time Between Pump Runs (Time to Fill).” “Time to fill” is basically the time it takes for sewage to fill a wet well and alert the pump to start running, effectively clearing the well of waste.

Figure 1: Blockages were detected and the utility notified 13 hours ahead of time.

Using historical data, Nukon identified the fill and pump-run behavior for different profiles: on-peak and off-peak, weekends and weekdays. “Normal fill” and pump behavior during these periods was identified for the sewage-pumping station site.

The Seeq model identifies blockages by detecting the absence of “normal fill and pump behavior” in real-time. For example, the absence of pump runs or extended fill time during peak times would signify an abnormality and possible blockage.

Results

Testing shows the Seeq model detects blockage 13 hours before spillage. The model can thus help field teams avoid spill incidents by providing real-time early warning of statistically significant partial or full blockages in the sewer network.

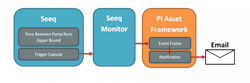

The model operates in real time. It uses pump-operating condition data from SCADA and field-telemetry systems, enters it into the model, and performs calculations continuously. When it determines that conditions are present for a spill, it creates an event notification to provide an alarm of the impending issue. The solution is integrated with the utility’s OSIsoft PI System Notifications [Figure 2] for early alerting. Alerts are issued directly to the Operational Control Centre and include Seeq live links, which enables investigation by engineers and collaboration with field crews in real-time to improve responsiveness.

Figure 2: The Seeq software monitors pump data in real time. If it finds a problem, it tells the OSIsoft PI System software, which issues a notification.

The on-peak/off-peak model was installed as the online sewer-blockage detection system for every sewage-pumping station in the Midway Point region. Each site’s specific behavior, deviations and grace periods were accounted for to reduce false positives.

The utility is pleased because each deployment is quick, low cost and does not require additional monitoring equipment at sites. The deployment helps to protect the environment by reducing the number of spills through early detection, and provides a number of other ancillary benefits.

At present, the new system is constrained to the Midway Point sites to allow for model-tuning. It will then be expanded to include additional high-criticality sewage-pumping stations, such as those in environmentally sensitive areas.

Andrew May is principal consultant for manufacturing, infrastructure and utilities at Nukon