Vortex flowmeter calibration & rangeability

Q: I have a question regarding vortex flowmeters and hope that you can clear it up. The line size is 3 in.; the flow is minimum 6 m³/hr, normal 20 m³/hr, maximum 22 m³/hr. The vendor suggested using a 3-in. Endress+Hauser (E+H) Prowirl vortex flowmeter with minimum flow 4.03 m³/hr, maximum flow 138.22 m³/hr. That unit has a three-point calibration (30%, 45% and 65%). My client has the following questions:

1. Why has the vortex flowmeter not been calibrated for a lesser span range of 0-25 m³/hr?

2. What happens if the flow drops below 4 m³/hr? Can you let me know if my selected size is acceptable or I should use a smaller meter? If I keep the 3-in. meter, is it possible to use it over this range of 4 m³/hr to 25 m³/hr? Also, as the flowmeter has a Foundation Fieldbus transmitter, is it possible to configure the span in the transmitter? W.Watson. / [email protected]

A: You did not name the process fluid, or even indicate if it is a gas, liquid or steam, therefore the correctness of selecting a vortex meter for the application can’t be checked.

Meter sizing: I usually select a maximum meter flow of 1.5 times the maximum process flow. Therefore, if your flow range is 6-22 (rangeability of 3.7), I would look for a maximum meter reading of 33 or so. The available ranges of this vendor’s meter are 1-34 for 1.5 in., 1.5-53 for 2 in., and 4-138 for 3 in., and therefore, I’d consider a 1.5 in. meter, but there are other considerations.

Reynolds number (Re): Assuming that the selection of a vortex meter is correct

Click the cover to get the full report.

and it’s on liquid service, the inaccuracy will be around 0.75% actual reading (AR) if the Re, even at minimum flow, is above 20,000. If it’s below that, you can expect an error of about 1.0% full scale (FS). So the smaller the meter, the less the error. For liquids, Re can be calculated using: Re = 3,160 Gf Qf / Dμ where: Gf: process fluid specific gravity at 60 °F (15.5 °C) Qf: liquid flow in gpm (1 m³/hr = 4.4 gpm) D: pipe inside diameter (in inches) μ: viscosity of the process fluid (in centipoises)

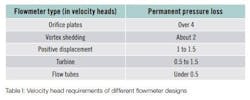

Pressure drop and operating cost: Obviously, the smaller the meter, the higher the pressure drop. Therefore, you must check if cavitation or flashing will occur, and even if they do not, you should also consider the energy cost of operation, which also rises as the size is reduced. (For the velocity heads of some flowmeters, see Table I).

The operating costs can be calculated as: $/yr = C($/kWh)(∆P)(F)(SpG)/(%) where: C: Correction factor for the units used (C is 0.65 if the flow is in gpm and the pressure loss is in psid) %: efficiency of the pump or compressor So, if the cost of electricity is $0.1/ kWh and the pumping efficiency is 60%, the operating cost in a water measurement application is:

$/yr = 0.635 (gpm) (psid)

Straight pipe run requirements: The meter should be installed at selfdraining low points or in vertical upward flows to keep it flooded, and five or more straight pipe diameters (D) upstream from all disturbance sources (regulators, valves, thermowells, pressure taps, etc.) in areas where there is no excessive pipe vibration. The upstream (inlet side) straight pipe diameter requirements are: 15D from a reducer, 20D after a single elbow, 25D after two elbows in the same plane, 40D after two elbows in different planes, and 50D after regulators or control valves.

Historical note: The vortex phenomenon was discovered by Tódor von Kármán while he was fishing in a fast spring in Hungary’s Transylvania region. He noted that the swirls that are formed after the rocks were the same distance from each other, no matter how fast the water was flowing. That observation became the basis not only of this flowmeter, but also of much of the science of space exploration. Béla Lipták / [email protected]

A: The 3 in. vortex is way oversized for your application. Normal rule of thumb for vortex flowmeter sizing is at least one line size smaller than the pipe size for most applications. Looking at your requirements, a 1.5 in. vortex would actually give the best results because it has an approximately 0.95 to 34 m³/hr range. A 2 in. meter would also do, as it has a range of approximately 1.5 to 53 m³/hr.

Vortex units are velocity meters. They rely on vortex shedding and require a certain minimum flow velocity to generate the vortices (the frequency is linearly related to the fluid velocity). However, below a certain velocity, you do not get vortices (and can’t measure flow). Each of the sizes measure the same velocity range (if they are the same style). The area then gives you the equivalent volume flow. All the vendor websites have technical details on how vortex meters work, including the basic equation. I suggest that you review the material. Simon Lucchini, CFSE, MIEAust CPEng (Australia) / Chief Controls Specialist, Fluor Fellow in Safety Systems / Simon. [email protected]

A: To answer your first question, the vortex meter can be spanned to something less than the maximum calibrated range. If you don’t specifically give them a different range, they will, by default, span the meter to the full range.

On your second question, if the flow drops below 4 m³/hr, the reading will drop to zero. This is called “lowflow cutoff.” A vortex meter requires the flow to be in the turbulent flow regime to function correctly. As the flow drops to the transitional (or laminar) flow regimes, it will stop shedding vortices and the meter reading will become erratic and then drop out. Note that the exact point where this occurs depends on the Reynolds number of the fluid, so if the density and/or viscosity are different than water, the actual low-flow cutoff point will vary from the published value. (The published value is based on water.) Most vortex manufacturers have programs that calculate the exact lowflow cutoff point for your application. (E+H has their Applicator program, which you can access online).

Finally, based on the little process information you provided, I would agree that 3 in. probably is oversized. A 2 in. meter has a minimum linear flow of 2.7 and a max range of 61.6 m³/hr, which is Flowmeter type (in velocity heads) Permanent pressure loss Orifice plates Over 4 Vortex shedding About 2 Positive displacement 1 to 1.5 Turbine 0.5 to 1.5 Flow tubes Under 0.5 Table I: Velocity head requirements of different flowmeter designs www.controlglobal.com -12- CONTROL: SPECIAL REPORT well within your specs. In fact, you could even drop to a 1.5 in. meter size. However, do note that that pressure drop will rise with each drop in meter size. In addition, you’ll need to reduce the pipe size far enough upstream and downstream of the meter to make sure you have a good straight run to obtain good accuracy.

Note that your 3 in. meter will work, but you’ll be unable to read much below 4 m³/hr. If low flows are expected, you’ll either need to downsize the meter or consider a different technology. P. Hunter Vegas, Wunderlich Malec / [email protected]

A: To the question on configuration, the answer is yes. Some handheld configurators are also capable of configuring Foundation Fieldbus instruments. You may use your Foundation Fieldbus configurator, which is often the DCS itself, or software for strategy building running on a PC attached to your Foundation Fieldbus network. This is the same software you would use to field test your device connection and set its tag name, limits, etc.

The device has an upper range limit and has a zero default for the lower range limit. You specify these values when you configure the AI function block for this flowmeter. E+H user manuals are available on the Internet at the E+H website. If you are using Foundation Fieldbus instruments, your DCS must supply software to configure all field instruments using the parameters of their DCS or Device Descriptions. Refer to the documentation from your DCS supplier.

You received a standard 3 in. vortex meter from E+H. Your meter was flow calibrated for the stated range. As delivered, the span of this meter is set for 0–138.22 m³/hr. If you had ordered this meter to be calibrated for your desired span of 0–25 m³/hr, they would have charged you more for the custom calibration, but you did not order that way. As delivered, the 20 mA output will have a span of 138.22 m³/hr. This is a HART instrument and the span can be easily changed to 0-25 m³/hr using a HART handheld (275/375) device. It is most likely to be even more linear over your reduced range than the original range. Dick Caro / [email protected]