RxM: What is prescriptive maintenance, and how soon will you need it?

By Sheila Kennedy, Plant Services contributing editor

Don’t just predict problems – prescribe a solution. That’s the premise behind prescriptive maintenance, which as a concept goes hand-in-hand with prescriptive analytics. Odds are you’ll be hearing these new buzzwords a lot more often in the coming months and years. But what is prescriptive maintenance, really? How does it work? And maybe of most importance, what can it achieve that other models can’t?

First, to better differentiate the words prescriptive and predictive, the word “prescriptive” here will be used interchangeably with “Rx.”

Rx maintenance is unique in that instead of just predicting impending failure, as predictive maintenance (PdM) does, it strives to produce outcome-focused recommendations for operations and maintenance from the Rx analytics. Though RxM is still in its infancy, many thought leaders are considering its potential to become the next level of reliability and maintenance best practice.

Analysts define Rx strategies

One of the earlier voices on prescriptive maintenance was Dan Miklovic, principal analyst at LNS Research (www.lnsresearch.com). “No longer will you need an ensemble of experts to tell you how and when to maintain your assets, as the assets themselves will tell you what they need if they are unable to fix themselves,” wrote Miklovic in a May 2016 blog post, “What Comes After Predictive Maintenance?”

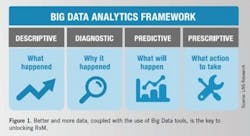

He suggested the acronym RxM at that time, and he continues to research the topic (see Figure 1). Better and more data, coupled with Big Data tools that can interpret things such as the content of repair manuals, is the key to unlocking the concept of RxM, Miklovic says today.It starts with prescriptive analytics, which not only tells you that a problem is likely to emerge, but also it gives you multiple response scenarios from which to choose. “Let’s say a piece of equipment is showing increasing bearing temperature,” Miklovic explains. “Predictive analytics looks at the temperature profile and tells you it is likely to fail in X amount of time. On the other hand, prescriptive analytics tells you that if you slow the equipment down by Y%, the time to failure can be doubled, putting you within the already scheduled maintenance window and revealing whether you can still meet planned production requirements.”

Another early follower of this trend is Ralph Rio, vice president of enterprise software at ARC Advisory Group (www.arcweb.com). “From my experience with clients from both the user and supplier side, the dominant application right now is PdM – prescriptive maintenance is beyond that; it’s new thought leadership,” he says. “But the goals of PdM and prescriptive maintenance are similar: to reduce unplanned downtime, which causes lost revenues, materials, and labor.”

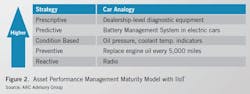

To help clients better differentiate the newer approaches from conventional maintenance strategies, Rio developed the Asset Performance Management Maturity Model (see Figure 2). The upper tiers of maintenance maturity – predictive and prescriptive maintenance – are both multivariate approaches. The current in a pump’s motor drive, the fluid going into the pump, its temperature, and the pressure going in and out can all be combined to better assess the health of the pump and motor, so you get longer advance warning of a failure and can make changes during a planned shutdown, he explains. The industrial internet of things (IIoT) provides the data, and analytics generate the alerts.

Prescriptive maintenance adds the ability to give advice to the technician on what to do and how to do the repair by taking advantage of artificial intelligence (AI) and machine learning. The math algorithms are more detailed, and there’s some intelligence added to give the technician some direction.

The three lower tiers of Rio’s model include single-variable condition-based maintenance, which provides less advance notice of failure; time- or cycle-based preventive maintenance, which is inefficient compared with higher-level models; and reactive maintenance, which occurs after failure. There is still a place for each of these approaches for certain assets that are not critical to operations or safety, Rio notes.

Peter Reynolds, contributing analyst at ARC Advisory Group, notes that organizations that shift critical assets to prescriptive approaches are seeing significant improvements in maintenance costs, service costs, plant availability, and worker efficiency.

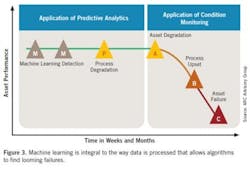

The unique abilities of analytics platforms make them capable of ingesting multiple data sources and storing, processing, contextualizing, and visualizing the predictions, he says. Machine learning is integral to the way data is processed, allowing algorithms to find looming failures (see Figure 3).“Machine learning detection occurs by using automated collection of historical multivariate data and analysis with equipment-specific algorithms,” Reynolds explains. “Pattern identification points to an explicit diagnosis of root cause and indicates a precise action to change an outcome. Prescriptive advice would include altering the process operation to avoid a future failure of the asset.”

Common drivers of prescriptive approaches

Several key business drivers are spurring interest in Rx strategies and driving solution development.

- Automation: As more automation is used in manufacturing, the speed of response required in dealing with maintenance issues is going to get faster, says LNS Research’s Miklovic.

- Economics: Decisions as to what’s the best option from an economic standpoint are getting more complex. “It just isn’t enough to know what can fail or when it might fail,” Miklovic says. “It requires having enough information to understand the options for maintenance as well as the financial implications of each option.”

- Workforce changes: Older workers are retiring, and newer, younger workers expect smart, assistive tools to help them do their job. Miklovic observes that the value in Google Directions is it gives users options and predicts times based on current conditions. He believes maintenance activities should be the same: For instance, to service a piece of equipment with an overheating bearing, you could either (a) take 20 minutes and grease it, and the repair would probably last two days, or (b) replace the bearing, which would take three hours but last for two years.

- Operating conditions: Assets not only fail by their own means, but also by the manner in which they are operated, notes ARC Advisory Group’s Reynolds. For example, a pump manufacturer will recommend specific operating design conditions such as discharge pressure and temperature, but there is a lot of variability in process operating conditions and also in the composition of the fluids. Prescriptive analytics can consider these conditions and make recommendations accordingly.

- Asset performance: Reynolds believes a higher level of sophistication is required in the way asset and process data are organized. “The traditional plant historian and analysis tools have not been adequate for ensuring asset performance,” he says. “IIoT and analytics platforms are unique in their ability to ingest years of operational data and massive quantities of unconventional data scattered through different systems of record.”

Early adopters are assessing the value

Elevator OEM and maintenance service provider thyssenkrupp Elevator (www.thyssenkruppelevator.com) favors cutting-edge maintenance strategies. Rory Smith, director of strategic development for the Americas at the company, says that at its core, prescriptive maintenance allows thyssenkrupp Elevator to focus on servicing elevators in the most efficient ways possible to increase uptime. Machine learning allows the use of data from the company’s vast network of elevators to better identify the service tasks most critical to maintaining a safe and reliable elevator.

“thyssenkrupp Elevator has a team of data scientists and domain experts working in unison to develop predictive models,” says Smith. “These models inform our service program, and paired with our network of skilled service technicians, are ultimately responsible for maintaining elevator uptime for our customers.”

The company’s predictive model continues to evolve thanks to machine learning, but it can already predict five days in advance when an elevator will shut down because of a door problem (see Figure 4). This early warning has proved to be highly accurate with no false positives, making it therefore invaluable to thyssenkrupp customers, Smith says.“With MAX, our PdM IoT solution, our computing power takes this a step further,” he adds. “Even before a service technician arrives on site, the expert system we refer to as ‘The Coach’ advises the technician on the four most likely causes of the problem, based on the data, with 90% accuracy. This means thyssenkrupp technicians can fix an issue on the first visit more than 90% of the time. The industry average for initial diagnosing is about half that,” he says.

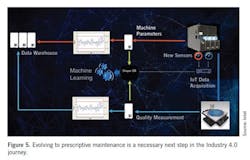

Intel prides itself on being at the forefront of research, development, and deployment of advanced technology for manufacturing, including frameworks to support prescriptive analytics (see Figure 5). Often, proofs of“Intel made the journey to PdM decades ago,” explains Mary Bunzel, general manager, manufacturing and industrial solutions at Intel (www.intel.com). “There are many examples of solutions we’ve developed with our partners being deployed in both our facilities and in our partners’ customer sites.” She adds, “Evolving to prescriptive maintenance, where probable cause and automated maintenance are implemented, is a necessary next step in the Industry 4.0 journey in order to keep up with the demands of fast-paced change in our market.”

A specific example of one such case study is a project recently implemented in Intel’s Ireland Fab plant, which addressed conservation of energy used to cool water for the production facilities. “By integrating sensed data from the outside ambient temperatures for areas the pipelines travel through, with the water temperature, the amount of energy used to cool the water has been reduced by as much as 40%,” says Bunzel. Energy conservation is a key imperative for Intel, so the return on investment (ROI) is far greater than just monetary savings alone, she adds.

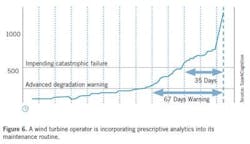

AI technology specialist SparkCognition is helping a wind turbine operator incorporate prescriptive analytics into its maintenance routine. “Because of the thin margins facing the wind industry today, turbines must be running at maximum capacity to get a full payback, and any amount of downtime cuts significantly into profits,” says Stuart Gillen, a senior director at SparkCognition (www.sparkcognition.com).

SparkCognition and its customers leverage data that is already available yet in many cases unused. Utilizing AI techniques, SparkCognition’s system is able to find patterns in large data sets that point to eventual failure. These identifying patterns can then be tracked and/or monitored and provide early warning evidence to subject matter experts, operators, management, etc., for work planning.

These systems are also able to incorporate unstructured data, such as work orders, parts databases, and operational and technical manuals, to provide a true prescriptive view. “Not only is the user now able to understand something is going to fail, but they are provided with evidence about how to address the problem. This provides dramatic savings to operators,” explains Gillen.

For example, for a single component on a single wind turbine, SparkCognition conservatively estimates the following annual cost savings from AI:

- Downtime savings: $1,000

- O&M savings: $2,500

- Total savings: $3,500

The wind turbine operator’s savings are expected to rise significantly from continued machine learning and also from the identification of more components for monitoring over time (see Figure 6).

Recommendations to asset users and suppliers

The market will determine whether Rx maintenance will become the ultimate best practice for reliability and maintenance, but those following the model closely are encouraging its adoption.

“Start now,” says Gillen. “What we are seeing across many industries is with very few sensors, which are typically already installed, information can be discovered leading to dramatic cost savings.”

RxM isn’t needed for every asset. It should be used where it makes sense, i.e. where the asset is critical to production (volume, quality, etc.) or to safety, suggests LNS Research’s Miklovic.

ARC Advisory Group’s Rio recommends using PdM on all of your critical assets because the predictive approach’s ROI has already been proved, and PdM has become less expensive and more sustainable with IIoT. He also encourages the supplier and user communities to do pilot programs to flesh out prescriptive technology.

“There is not a barrier to prescriptive from the technology viewpoint,” says Rio. “The next step is really to understand how the technology would be melded into products and designed in a fashion that can be applied by end users and deliver ROI.”

Rio advises that to facilitate this effort, organizations should engage with a global service provider that already has all of the necessary IIoT technology skills available to it, in particular those pertaining to industrial automation, DCS and PLC systems, data historians, networking, the cloud, and security.