Conducted in August and September 2015, the survey of 351 manufacturing companies was sponsored by Rockwell Automation, QAD and BDO, and was designed to evaluate the readiness of U.S. manufacturers to incorporate smart devices and embedded intelligence within their processes and products.

“We’re particularly interested in executives’ plans to improve business performance via the IoT—and for developing and selling products with embedded intelligence,” adds George Taninecz, MPI Group vice president of research. “The study looks deeply into how manufacturers will leverage IoT capabilities along with the challenges they face.”

The balance of this article includes a number of the key insights revealed by the research. For more information on the complete report, “Profiting from the Internet of Things (IoT): How IoT Innovators Make It Happen—and What You Can Learn,” visit www.MPI-group.com.

Innovators, Incipients and Indifferents

Many manufacturing companies have a limited understanding of the IoT or how to apply it to their businesses. In fact, poor understanding of IoT principles and its potential implications was found to be highly correlated with a lack of best practices and poor performance measures.

Respondent were sorted into three groups based on their abilities to grasp, leverage and profit from the IoT (Figure 1):

• Innovators: These firms are leaders in intelligent manufacturing, and set the benchmarks for best practices and performance. A third of manufacturing companies have achieved this level of IoT understanding—and how to apply it to their businesses.

• Incipients: These companies have a vision of how they could leverage the IoT, but still have a long way to go. Some 43% of manufacturers are stalled with limited awareness of the IoT’s potential.

• Indifferents: These organizations have no understanding of the IoT. Some are indifferent by design—willfully ignoring a future that will soon pass them by—while others lack the resources to adopt an IoT strategy. About a quarter of all manufacturers are stuck here.

While Innovators are more bullish on the IoT than Incipients or Indifferents, executives at all types and sizes of companies believe that over the next five years the IoT will impact business in general (71%) as well as their own businesses (64%).

But when it comes to IoT strategy, Innovators are far more likely to have developed and implemented strategies for applying IoT technologies to their own manufacturing and business processes as well as for embedding IoT technologies into the products they sell. Many Incipients are in the planning stage, but Indifference runs deep: more than a third of all manufacturers say they have no plans (really?) to develop an IoT strategy for process or products.

Further, a good understanding of the IoT is a strong indicator of better operational performance. Two-thirds of innovators have fully achieved or made significant progress toward world-class manufacturing status. Indifferents, on the other hand, are also indifferent to manufacturing success; a whopping 73% have made—at best—only some progress toward world-class status.

Intelligent plants and processes

Overall, manufacturers have incorporated smart devices or embedded intelligence in 25% (median) of their production equipment and processes as well as non-production processes (e.g., back office). Yet 76% will increase the use of smart devices of embedded intelligence in production processes in the next two years; 66% will increase non-production IoT applications. Shipping, warehousing and document management are seen as the best opportunities to leverage the IoT in operations (Figure 2).

- Improve product quality (58%)

- Increase speed of operation (57%)

- Decrease manufacturing costs (57%)

- Improve maintenance/uptime (47%)

- Improve information for business analytics (42%)

The top five IoT capabilities that present the biggest challenges are:

- Identifying opportunities/benefits of the IoT (44%)

- Network capabilities to handle the IoT (38%)

- Budget/resources to develop or expand the IoT (37%)

- Incorporating smart devices or embedded intelligence (37%)

- Adapting existing technologies (36%)

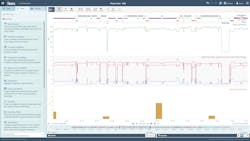

Effective use of the IoT requires more than just technology: operations technology (OT) staff need to collaborate with information technology (IT) staff. Yet most OT and IT departments don’t currently work together much (Figure 4).

Other top-level findings relevant to organizational applications of IoT technology:

- Only 30% of study participants think that security is an IoT challenge. Roughly half have implemented, developed or are considering a BYOD (bring your own device) policy for non-corporate devices (e.g., smartphones) in plants.

- Operations leadership is most likely to lead an IoT strategy (26%), followed by a cross-functional leadership structure (19%) or IT leadership (17%).

- About two-thirds of manufacturers have invested 2% or less of sales in implementing the IoT. Yet 77% of manufacturers expect to increase investments in the next two years.

- Roughly two-thirds of manufacturing executives believe that the application of the IoT to plants and processes will increase profitability over the next five years.

[callToAction]

Intelligent products

The IoT also holds the potential to transform manufacturers’ businesses through the inclusion of connectivity in manufactured products. A substantial portion (40%) of manufacturers indicate they have plans to embed smart devices in their products (Figure 5).

- Increase revenue from new products (39%)

- Increase market share (39%)

- Access data from products or services in the field (34%)

- Increase profit margins per product (34%)

- Improve branding/market awareness (27%)

- Access new markets/sectors (26%)

The top five challenges faced by companies pursuing IoT-enabled products are:

- Identifying opportunities/benefits of IoT-enabled products (44%)

- Clear understanding of customer needs/value (36%)

- Technologies needed to embed smart devices into products (35%)

- Budget/resources to develop IoT-enabled products (32%)

- How/where to get started with IoT-enabled products (29%)

About three-fourths of manufacturers have invested 2% or less of sales in embedding IoT technologies in products. But more investment is likely: 67% of manufacturers expect to increase investments in the next two years. Roughly 63% manufacturers believe that applying the IoT to products will increase profitability over the next five years.

Profile of Study Participants

Some 60% of the 351 manufacturers participating in the MPI Internet of Things Study are private companies. A large majority (84%) have been in business for more than 20 years. Participants represent a range of annual revenues: 35% have revenues of $50 million or less, while another 36% have revenues that exceed $1 billion.

The top five industries in the study are:

- Machinery manufacturing (21%)

- Food manufacturing (14%)

- Fabricated metal product manufacturing (12%)

- Chemical manufacturing (11%)

- Electrical equipment, appliance, and component manufacturing (11%)

Almost all participants had facilities in the United States (96%), and more than one-quarter had facilities in Europe (43%). Respondents also had facilities in Asia, not including China (32%); China (31%); Mexico (30%); and Canada (28%).

For more information on the complete MPI study, “Profiting from the Internet of Things (IoT): How IoT Innovators Make It Happen—and What You Can Learn,” visit www.MPI-group.com.