This could be the start of something big. Just as the commercial and social Internet have transformed how businesses interact with customers and individuals with one another, industry is poised for a new wave of performance improvement delivered by ongoing and dramatic advances in connectivity and computing technology.

“Increasingly, being connected is seen as a basic human need,” says Klaus Helmrich, member of the managing board for Siemens AG with responsibility for the company’s Digital Factory initiative. Connectivity is expected in the workplace and among the systems we use there, Helmrich says. In fact, “Everything between users and the businesses providing such products and services is changing.”

Germany-based Siemens, like GE, its nearest industrial conglomerate counterpart with U.S. roots, are at the same time head cheerleaders, technology suppliers and user beneficiaries of the ongoing digitization and “data-fication” of industry. Variously labeled as Industrie 4.0, the IIoT, or simply the Industrial Internet, each of these parallel initiatives has at its core the value to be gained by the pervasive connectivity and integration of devices and software applications across industry. “The approaches are somewhat different,” notes Armin Pühringer, business development manager for Hilscher, a specialist in industrial connectivity solutions. “But the Industrial Internet and Industrie 4.0 are made of same metal.”

Siemens’ Helmrich delivered the comments above in a press conference at April’s Hanover Messe, Germany’s leading industrial trade fair. Here, even the event theme of “Integrated Industry - Join the Network” played to that country’s intentions to lead this latest industrial revolution.

Cross-domain integration

Clearly, the potential for easier, cheaper and more meaningful integration of formerly siloed systems across functional domains and extended supply chains holds enormous potential to improve performance and enable new, transformative business models. But industrial operations can also carry unique requirements in the categories of system reliability, determinism and security, as well as the challenge of an enormous and heterogeneous installed base of legacy equipment and network protocols.

On the positive side, determinism is relative; cyber security isn’t an all-or-nothing proposition; and reliability can be addressed through redundancy and other measures. Meanwhile, technology suppliers are hammering out just what standards and models are needed to streamline the robust and resilient integration of today’s multi-vendor ecosystems with an eye toward enabling tomorrow’s increasingly intelligent and autonomous systems.

But there’s not yet—and likely never will be—agreement on a single, standard way to accomplish all that could be done. The good news is that much of the essential functionality that industry needs to get started already exists in the form of standards originating on both sides of the operational technology (OT) and information technology (IT) divide. Indeed, the underlying technologies necessary to connect and manage the relationships among billions of devices and associated cloud-based applications have been demonstrated in the worlds of telecommunications and mobile social media.

“In some ways, manufacturing is where IT networking was in the early 1980s,” notes Kip Compton, Cisco’s vice president and general manager of IoT systems and software, recalling the days when DECnet, SNA and other proprietary networks wrestled for market dominance, ultimately conceding to open standard TCP/IP over Ethernet, which since became the backbone of the Internet. “In fact, the roots of Cisco are in a multi-protocol router designed to bridge these networks,” Compton says. “The economics for increased standardization are just now lining up in the industrial space.”

“What’s different today is the rate of change of technology,” adds Beth Parkinson, market development director for Rockwell Automation’s Connected Enterprise offering. “The use cases that were cost-prohibitive before are now possible,” she says. The rise of IIoT also has sparked other, more fundamental questions among senior decision-makers, -Parkinson adds. “What is our business? What can our business offer our customers? What will our competitors offer? The landscape is changing; will we have the flexibility to compete?”

Governments, consortia look to fill gap

Even government policy-makers have recognized the potential for digital computing and communications technology to substantively improve the performance of industrial operations. This gathering momentum has coalesced into a range of government-led efforts including Germany’s Industrie 4.0 movement, China’s “Internet Plus” investment action plan, and the establishment by the U.S. of a Digital Manufacturing & Design Innovation Institute in Chicago. Technology suppliers, too, have joined forces to advance the cause, notably as the Industrial Internet Consortium, which began in the U.S. but now includes 159 member companies based in 22 countries among its rapidly expanding ranks. Standards-making bodies are hard at work, too. And the coordinated progress of Industrie 4.0 member companies is being tested out at the SmartFactoryKL demonstration unit in Kaiserslautern, Germany.

Both the IIC and Industrie 4.0 groups have created reference architecture documents that, if nothing else, illustrate the subtleties and complexities of the challenge at hand. The Reference Architecture Model Industrie 4.0 (RAMI 4.0) is a high-level document describing a three-dimensional model based on the relevant IEC standards for control and enterprise IT functionality juxtaposed against product and asset lifecycle value streams (Figure 1). “Based on this framework, Industrie 4.0 technologies can be classified and further developed,” wrote Martin Hankel of Bosch Rexroth on behalf of ZVEI, the German Electrical and Electronic Manufacturers Association, of the not insubstantial development work that remains to realize its vision.

Figure 1. The Reference Architecture Model Industrie 4.0 (RAMI 4.0) sets the functional hierarchy of industrial/manufacturing operations against the product and asset life cycle and value stream.

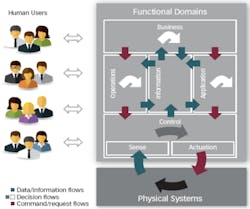

The IIC, on the other hand, recently completed a draft Industrial Internet Reference Architecture that goes to great lengths to define, from a functional perspective, the various aspects of Industrial Internet systems (Figure 2). The 100-page document is about to be publicly released as of press time. Next steps for the IIC will be to “identify existing standards and technologies, organize them, and then identify gaps between what the standards address and what is now needed for Industrial Internet systems,” according to a recently published update. The IIC intends, in turn, to write requirements for standards to fill those gaps and send them to expert organizations that can build such standards.

Figure 2. The Industrial Internet Consortium will soon release an Industrial Internet Reference Architecture (IIRA) that systematically addresses the performance requirements of the systems of systems that comprise the industrial internet.

Complete standards can wait

There exists an alphabet soup of existing standards to consider. Some, such as DDS and MQTT, already facilitate real-time data transport in very large, highly distributed systems. Think air traffic control systems, U.S. Navy ship movements and Facebook Messenger. Other standards such as OPC UA and PackML bring to the game the higher levels of industry-specific -semantics that will be necessary if the ultimate goal of resilient systems of autonomous and composable components is to be realized.

Meanwhile, hitch your wagon to suppliers that leverage open standards where available and you’ll be best prepared as technology standards continue to evolve,” says Bernie Anger, general manager for GE Intelligent Platforms’ Control Solutions & Embedded business. “We are recommending that customers bet on extensible and extendable standards wherever possible,” Anger says.

In the end, business waits for no standard. Where need meets opportunity, industry already is deploying ever smarter edge devices and networks to enable the distributed execution of analytics and other applications to accelerate decision-making. A heterogeneous mix of legacy plant-floor equipment and specialized protocols will persist for some time to come, but industrial organizations with an eye to the future already are developing migration strategies to bring their networks forward. Companies that wish to move quickly into the IIoT already can buy increasingly capable IIoT infrastructure and software-as-a-service from a growing list of platform providers. And established providers of application software and solutions are already taking advantage of the new possibilities to deliver tangible returns on behalf of their customers.

We take a closer look at each of these frontiers in the articles that follow in our special June 2015 edition of Smart Industry. See other articles from this issue.