Base Camp Digital Preview: Intel's Irene Petrick on success with scaling

This week, Irene Petrick shares her expertise during the Base Camp Digital webinar “Digital Twin, Asset Behavior and Other Strategies to Jumpstart and Sustain Digital Transformation.” Today, the senior director of industrial innovation with Intel’s IoT Group previews her presentation. Take a look…

Smart Industry: Two of three digital transformation pilots fail to scale. What's a common reason for that?

Irene: The most common reason for pilots that fail to scale is that the pilot planning didAnother reason that pilots fail to scale is often beyond the confines of technology challenges. Instead people and processes are often the root of the problem. Simply digitizing an existing process does not necessarily add value. Processes need to be reconsidered in light of what digital solutions could enable. IoT solutions cross traditional organizational siloes and often require cross-functional communication/cooperation.

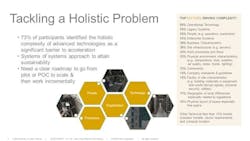

The slide below highlights the complexity of the IoT problem. We call this holistic complexity. It is not just one thing that needs to be dealt with. Instead, there are significant interactions between what might otherwise be standalone issues in traditional solutions. We have data from 193 technologists in manufacturing and the ecosystem companies that support them. You can see from the slide below some of our findings. 73% of participants called out this holistic complexity as being a major barrier to acceleration.

Getting smarter—companies that are taking a system-of-systems approach and looking at the interdependencies between people, processes, organizational culture and technologies are the ones that are having more success in getting beyond pilot purgatory.

Smart Industry: What's a key trait among innovative companies that are successful transforming?

Irene: From an IoT perspective, the companies that are most successful are the ones that begin with a vision of what IoT technologies might do for their company from a business-value perspective. These companies understand the magnitude of the changes that will be needed to realize that business value. Then these companies begin to execute in an incremental way. Here each project is a piece of the whole rather than a standalone effort. With standalone efforts, we end up with pockets of excellence that don’t draft on one another.

The really successful companies identify metrics that they will use to track the projects they initiate. They understand before they begin that learning will be needed as the project progresses and they set goals and metrics to track these goals. It is not a retrospective look back at whether or not a project was successful. Instead it is a journey. The slide below captures the breadth of metrics that can be employed to assess the success of projects over time.

Smart Industry: What is one of the key strategies to jumpstarting a transformation, particularly if it's a first effort?

Irene: In a first effort it is essential to know what problem you are attempting to solve. Deploying a solution that is “cool” but that doesn’t deliver business value happens more than you might expect. A deep appreciation of the problem space—and the various parts and people within the organization who are associated with that problem—can accelerate success. Another thing that novices in the IoT- implementation space need to consider is the solution providers and the way that they will interact together to actually deliver a fully-formed solution. IoT technology solutions depend on many components to deliver value and these components are often provided by more than one vendor. The fragmented nature of the ecosystem of IoT solution/component suppliers confounds most new initiatives, and remains a serious problem even among experienced operators.