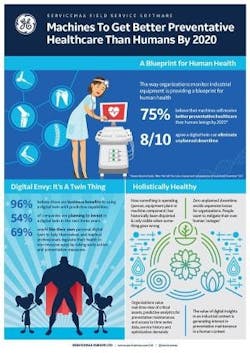

Machines getting better healthcare than humans by 2020?

A new study from Vanson Bourne, sponsored by ServiceMax, from GE Digital, has found that 75% of IT and field service leaders believe that machines will receive better, preventative healthcare than human beings by 2020.

IT and field service leaders surveyed believe advancements in machines' ability to predict failure and take preventative measures is widely viewed as beneficial to a company’s bottom line. For example:

- 46% of respondents say machines requesting help will enable companies to better manage their equipment assets.

- 39% of respondents say predictive maintenance would help manage asset equipment.

- 44% of respondents say digital twin with predictive maintenance and artificial intelligence would help prevent major failures.

- 69% of respondents say they would like their own personal digital twin to help themselves and medical professionals regulate their health in non-invasive ways by taking early action and preventative measures.

“In the same way that organizations want zero unplanned downtime with their equipment assets to avoid expensive loss of production or service, we want to mitigate our own human ‘outages’,” said Mark Homer, VP of global customer transformation for ServiceMax, from GE Digital. “This holistic view of how something is operating–whether it’s a person, an equipment plant or an individual component in a machine–has historically been disjointed and only visible when something goes wrong. Today, organizations are acutely aware of the value of a real-time view on the health and performance of their critical assets, as well as predictive analytics on when preventative maintenance or intervention is required, and access to time series data, service history and optimization demands. The research found that more than half of companies are planning to invest in a digital twin in the next three years. The value of these digital insights in an industrial context is starting to generate interest in preventative maintenance in a human context.”

A copy of the Vanson Bourne Whitepaper, Executive Summary and Infographics, can be downloaded here.