However, our recently completed Smart Industry “State of Initiative” survey, conducted by Putman Media paints a detailed picture of how IIoT is rippling across a wide swath of the manufacturing industry. For instance when asked how IIoT would affect their organization over the next five years, more than 40 percent envisioned a high impact and less than 7 percent “no impact.”

Few are standing still and waiting to see what will happen. Indeed, more than 21 percent of respondents say they have identified IIoT opportunities and have secure funding for initiatives. Another 32 percent are in the process of identifying a pilot project, while 46 percent described their organization as still “at the starting gate.” None of those surveyed claimed to have achieved IIoT benefits with only their existing investments in place.

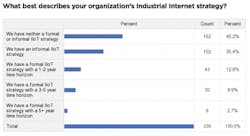

And what are the plans and strategies? Consistent with a phenomenon that has only been getting big attention for a few years, only a few companies have formal plan – and a tiny group (2.7 percent) say their plan extends to five years and beyond. Nearly half have no formal strategy and another 30 percent, only an informal one. Those that plan, also do. Some 20 percent of respondents claim to review their IIoT strategy at least once a month – compared to a slightly higher 26 percent who “never” review their strategies. That’s what they say now, but our guess is the `nevers’ will be disappearing quickly in the near future…

However, there is obviously some perplexity across the industry regarding where to go with IIoT, and how. For example, there was a wide diversity of views about the most important potential IIoT benefits. Optimization of asset utilization, reduced operational costs, improved worker productivity and safety, improved sustainability, enhanced customer experience, or even the creation of new business models and revenue streams were not ranked that far apart.

Respondents were much more clear about what they believe are the main obstacles to IIoT adoption. Ranked in descending order, the top three were security, a lack of overall IIoT business knowledge and a belief that their “products or services do not have an obvious Industrial Internet element.”

So, clearly, IIoT is on almost everyone’s radar screen. The early adopters are pushing ahead. And a lot of other organizations are engaging cautiously and trying to find their own sweet spot for implementation.

See the results of the survey.

Alan R. Earls is a Boston-based writer focused on technology, business, and manufacturing — a field where he spent the earliest part of his career. He has written for publications and websites as diverse as The Boston Globe, Computerworld and Modern Infrastructure as well as Industry, The Manufacturer, and Today's Machining World.