IT AS OPERATIONAL ADVANTAGE

“Counting beans is not the same as making them,” notes Dennis Hodges, chief information officer for Inteva Products, a global supplier of engineered components and systems for the automotive industry as well as for the defense, commercial vehicle and other markets. Indeed, an underlying theme of his work has long been applying information technology to not only keep the financial books for the enterprise but to improve the manufacturing processes themselves. “We might start with a basket of plastic pellets and transform it into a dashboard. That’s where technology can do something meaningful,” Hodges says.

Over the nine years Hodges has been with Inteva, he’s seen IT come together with operations and engineering to share a common perspective focused on making the company succeed. As a result, a big question today is whether the company has enough IT resources to deploy the technologies that operations is demanding. For example, he and his global team of IT professionals currently are automating the creation of quality control documents as part and parcel of the company’s production processes. He attributes this drive to eliminate manual operations to industry’s growing emphasis on traceability. “It’s not shoot and ship anymore.”

Haresh Malkani dreams of "self-aware, self-optimized manufacturing."

Longer term, Hodges sees additive manufacturing as having an outsized impact on the company’s manufacturing processes. “How we make things will change dramatically. With 3D printing it will be one part today, another tomorrow.” The Industrial IoT also promises to remake the company’s maintenance practices and reduce unscheduled downtime. “Today, there are half-million-dollar injectionmolding machines that effectively run blind,” he says. “It’s a multi-billion dollar opportunity, and there’s a huge opportunity for machine builders to provide those capabilities.” Meanwhile, Hodges and his team will continue to apply technology to enhance operators’ capabilities and eliminate another type of “3D” tasks—those that are dirty, difficult and dangerous for human operators.

In his 47 years in the elevator business, Rory Smith has pretty much seen it all. He’s set up maintenance operations in the Middle East, deployed high-performance elevator controls in the twin towers of the World Trade Center, and performed just about every function in between. But for the past three years the director of strategic development for ThyssenKrupp has lived and breathed IoT, overseeing the elevator manufacturer’s ambitious plans to connect the its vast installed base of 1.2 million elevators to the cloud.

“Our long-term business is maintenance,” Smith explains. Elevators are one-time capital placements that can remain in service for a century, but keeping them operating smoothly provides a steady stream of revenue. To ensure ThyssenKrupp remains the vendor of choice, the firm’s development team determined it could shift away from preventive maintenance to a predictive maintenance model, leveraging Microsoft’s Azure platform to remotely monitor performance.

The roll-out began late last year and continues at a torrid pace: Some 1,000 elevators are being connected each day via cellular connection to the cloud. The goal is to use a combination of remote monitoring, machine learning, cloud analytics and assisted maintenance to transform the reliability of its fleet and redefine customer service expectations.

“We’re already seeing phenomenal results,” Smith says. “We can predict with 80% accuracy that one of our most common failures will occur within the next seven days.”

A DRIVE TO INNOVATE

As founder and president of Global Drilling Support (GDS International), Keith Holliday has led the 20-year-old supplier of top drives and associated support services for oil and gas production in its efforts to leverage data on behalf of its clients. “Just five years ago, the focus was on building the best top drive—one that was big, fast and strong. But that’s no longer enough,” Holliday explains. Today, the company is developing software that with new sensor technologies will deliver better production efficiency for drilling contractors and their customers in the oil and gas industry.

For example, the company has implemented GE’s Equipment Insights solution to provide remote connectivity to their top drive controllers together with cloud-based analytics so that key performance indicators across their fleet can be gathered and analyzed in real-time. They’re also experimenting with the integration of vibration data for predicting maintenance requirements as well as downhole sensors. Downhole data together with new algorithms promise to improve drilling performance, much like anti-slip algorithms in a car’s transmission, Holliday explains.

Keith Holliday is building smarter top drives for the oil industry.

principles a s well as contributing alternative—and often more cost-effective—solutions to production challenges. “We’re a manufacturing company that runs thin margins,” Masker notes. “People and resources are thin, and that often means we have to come up with different ways of approaching problems.”

One example is the open-source Kepware Proxy middleware application the two developed in order to emulate communication between new programmable logic controllers on incoming machines through Kepware’s IoT Gateway to the plant’s JD Edwards ERP software and other plant databases. The middleware allows them to test all of the communications—without the PLC itself—so they know they can get the application up and running right the first time.

More generally, Kepware Proxy is an open-source middleware application that glues together manufacturing and business contexts, explains Misztur. “This means that machine data becomes available to the business and business data becomes available to machines.” The open-source software is available free of charge, and “we want other people to work with us to make the software better,” Misztur adds. To that end, interested parties are encouraged to visit his appropriately named website, MrIIoT.com.

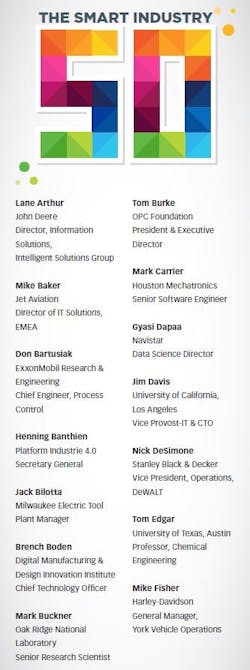

As president and executive director of the OPC Foundation, Tom Burke has been the face of OPC and the organization that supports it since the original specification was first conceived in the mid-1990s as a means to take on Wonderware’s dominance in the arena of software connectivity with thirdparty devices. Since that time, Burke has been at the helm as the OPC standards for open connectivity and application integration have continued to evolve and stay relevant despite the continued onrush of technology. Today, more than 440 companies belong the Foundation and it boasts cooperation agreements with 25 industry groups ranging from the newly formed OpenFog Consortium to the venerable German Machine Tool Builders’ Association.

Looking back over the past two decades, Burke is most proud of the organization’s ability to recognize and address a fundamental industry need, then bring together a range of competitive interests to develop specifications and technology to help solve real-world problems. “It’s all about people, and how we have assembled a cohesive team of individuals across competitive companies—all of us collaborating to deliver value for end users.”

Currently, Burke is focused on bringing forward the many legacy systems in place today to fully participate in the next generation of intelligent systems represented by Industry 4.0 and the Industrial IoT. “From when I started in this business 30 years ago, we’ve come full circle,” Burke says. “Open source technology is becoming more and more appropriate for different vertical industries and OPC has taken the initiative to open source all of our technology, and we’re working to increase awareness and adoption into markets beyond industrial automation.”

DATA-DRIVEN INNOVATION

There’s an old adage that too much knowledge about how sausage is made will diminish one’s enjoyment of the finished product. But at Tyson Foods’ Hillshire Brands subsidiary—maker of the popular Jimmy Dean breakfast sausages—operations personnel are enjoying the benefits of improved visibility into their manufacturing processes.

Jonathan Riechert, senior corporate engineer-innovation, led the company’s first foray into improved visibility, deploying data historian and visualization tools from Rockwell Automation for the company’s cooking processes. “The new tools helped to solve a problem that we wouldn’t have been able to diagnose without the data,” Riechert says. “And the ability to prove out the solution’s value—without knowing it in advance—made it easier to justify other applications.”

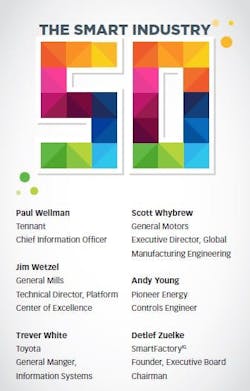

Detlef Zuhlke proposes modular production unites like Lego blocks.

Riechert’s passion for innovation and continuous improvement has its roots in his early work as a plant electrical engineer, out on the plant floor, working with maintenance, repeatedly fixing the same things that broke every day. “I thought, there has to be a more permanent fix—this is insane,” Riechert says. Today he continues to work on ways to make Tyson’s operations personnel more productive and effective, experimenting with wearable technology such as Google Glass for hands-free delivery of operating manuals. He looks forward to the day when more and more people will have access to the data and information they need to make better decisions. “I hope that in the years to come we have a better handle on plant data, and are building better interfaces for the people who need them.”

THE ROOTS OF INDUSTRY 4.0

Detlef Zuehlke stumbled into the field of factory automation. He started as an electrical engineering student with an interest in semiconductor design, but faced with no funding he switched to mechanical engineering and a focus on automation. The rest, as they say, is history. After graduate school he went to work for Lufthansa, then Boeing, and since 1994 he’s been chair for production automation at Germany’s Kasierslauten University of Technology.

Along the way, he founded in 2005 SmartFactoryKL, an industry-driven research and demonstration center for smart factory technologies that is recognized as the birthplace of the Industry 4.0 paradigm.

Today, as industry embarks on a new era of digital transformation, he cites lessons learned in the 1980s era of Computer-Integrated Manufacturing (CIM) and the Manufacturing

Lui Qiao sees material sciences as enabler of the digital economy.

Automation Protocol (MAP). Those experiences taught him not to underestimate complexity, and to consider the power of both market and technology forces to shape the future of technology.

“Our work today is driven by the need to remove complexity, to design production equipment that is modular and as easy to set up as Lego bricks,” Zuehlke explains. “We need standards to plug it all together and handle the essentials, then we can focus on orchestration.”

Production also will be moving closer to consumption, Zuehlke predicts, and with it manufacturing will return to regions abandoned in the pursuit of low cost labor. That raises the central question of how to get people to where they are needed, and how to train and educate them. “Production is coming back, and with it the requalification of the staff that will be needed to support it.”

CHAMPION FOR OPEN PROCESS AUTOMATION

Over the course of several decades, Don Bartusiak has seen the practice of process automation move from the cutting edge of computing, control and communications technology to one that advances relatively slowly, consuming technology rather than creating it. His hope is that the Open Process Automation initiative, a movement he spearheads as chief engineer for process control at ExxonMobil Research and "Engineering “will reinvigorate what we do in control.”

“When we as an industry moved to embrace commercial off-the-shelf technologies, we incurred many of the costs but few of the benefits,” Bartusiak explains. “Proprietary architectures and communication protocols are no longer justifiable, and software needs to be more portable.”

To these ends, ExxonMobil has engaged with Lockheed Martin to build a proof-of-concept open process automation system that will “catalyze industry change,” Bartusiak says. A second goal is to build a consortium of involved parties to “define an open, secure and interoperable architecture for the future.” To that end, a group dubbed the Open Process Automation Forum has been formed under the aegis of the Open Group, with a plan for a first member’s meeting in San Francisco, November 16-18, 2016. Bartusiak encourages all stakeholders—solutions providers, engineering firms and especially other end users—to get involved and to make their voices heard. “Mostly, the technology to make this a reality exists already,” Bartusiak adds. “The bigger change is to business models, and to relationships within the ecosystem.”

DIGITAL CHANGE AGENTOver the past 25 years, family-owned SugarCreek has transformed from a raw bacon manufacturer with $50 million in annual sales to a widely diversified, $600 million food company. And in the past 15 years, its business processes have undergone a digital transformation to match. Not coincidentally, SugarCreek’s digital transformation began to gather steam when Ed Rodden, now chief information officer, joined the company to help rescue a foundering ERP implementation. “Across all our plants, there wasn’t one person who had worked with an ERP system,” Rodden says. “Now we’ve has gone from a pencil-and-paper organization to one that uses the latest technologies.”

It wasn’t Rodden’s first foray into ERP, having cut his IT teeth during the “pre-laptop” era at a West Coast company, “doing new things with the latest minicomputers.” An early 1980s ERP implementation thrust him into all aspects of the operation, from inventory control to scheduling to financial statements. Thus began a series of roles of increasing responsibility that took him into sales, marketing and international operations. But travel took a toll on family life, and he left for quieter country near Cincinnati, Ohio, where at SugarCreek he found a match for his talents.

Mark Buckner believes in the power of cross-functional teams.

Under Rodden’s leadership, SugarCreek’s Information Technology Group has become “a highly focused business change agent, driving the business towards its strategic goals,” the company says on its website. Indeed, it’s the people side of the business that Rodden finds most satisfying: “The opportunity to relate to, to develop and motivate a group of people that are smarter than me.”

Looking down the road 10 years, Rodden predicts that the user interfaces for technology are overdue for an update and will be very different than they are today. “Pokémon GO gives us a hint of what will be happening,” Rodden says, predicting the expanded use of technologies such as augmented reality and voice in industrial contexts. Data tools, too, are ripe for improvement. “We’re collecting massive amounts of data, but the shortcoming today is in the visualization and preparation.” In particular, he’s bullish on the potential of graphical databases such as Neo4J to dramatically improve data accessibility (he wants out of the “SQL view” business). Machine learning and algorithms for users—not coders—also are needed. All toward the end of “getting data into the hands of the all the folks who can use it,” Rodden says.

SYNTHESIZER AND INTRAPRENEUR

Mark Buckner has built a three-decade career out of bringing things together. Sometimes it’s disparate ideas and technologies that when combined deliver new value. But even more exciting for the senior research scientist at Oak Ridge National Laboratory is bringing people together. As industry looks to advance its digital transformation and build the complex systems of systems represented by the Industrial IoT, “we’re going to need interdisciplinary, cross-functional teams that bring together a broad range of skills,” Buckner says. The world’s youth also are key, adds the FIRST Robotics team mentor. “We need to tap into the creativity of the next generation to take on the world’s gnarly problems.”

As evidence of Buckner’s passion toward solving the world’s problems—through technology and the applied brain power of today’s youth—one need look no further than center stage at National Instruments’ recent NIWeek event in Austin. Buckner, who currently leads ORNL’s Power & Energy Systems Group, demonstrated with a cadre of graduate students ongoing work to address the problem of connecting unpredictable renewable energy sources to the electrical grid. Central to the demonstration was the use of time sensitive networking (TSN) technology over standard Ethernet to successfully synchronize the phases of various loads and renewable power sources as they came off and on a microgrid that, in turn, was seamlessly synchronized with the larger electrical grid.

A self-proclaimed serial intrapreneur within ORNL, Buckner strives to take ideas and to

Chris Misztur solves problems on the far side of the IT/OT divide.

rapidly implement them in the real world and has successfully done so in the areas of signal processing, machine learning and computational intelligence. He believes that biomimicry holds enormous opportunities to help solve next-generation problems associated with digital transformation. For example, what can we learn about computer architecture from the human brain and how it handles enormous amounts data as well as abstracted information using only 20 watts of power? “There’s also plenty of space to solve base needs of society,” Buckner adds. “If we could provide affordable electricity and clean water globally, think of the creative capacity that would be unleashed. What kind of questions could we ask then?”

A PASSION FOR COMPLEX SYSTEMS

Mark Carrier isn’t always understood by his peers or management. He’s a long suffering advocate of data-centric software architecture, a liberating approach to the design of complex systems that he says isn’t always appreciated by those used to the flow of control rather than the flow of data. “Complex systems are my passion,” says the senior software engineer for Houston Mechatronics, a company started by NASA roboticists to develop new applications for space technology back here on planet Earth.

“People often think in terms of a single controlling entity and end up with large, over-engineered systems,” Carrier says. Instead, picture a pit crew, a federated system of autonomous actors. “Each has domains of responsibility and authority, and when the race car comes in they each know what to do.” This concept has enormous implications for the design of other complex systems such as robot movements, where the ultimate destination typically is more important than the path taken. “The challenge is teaching people how to start bundling low level functionality into higher level abstractions,” he says.

Further, when things are centralized, upgrading is painful or impossible, Carrier says. “But with a data-centric architecture, remove one component and the others still know what to do.” Carrier hopes to continue developing these concepts and see them successfully applied within the oil and gas industry, for example, to subsea activities or the robotic replacement of drill bits in the oilfield. “It will fundamentally change industry processes,” he says, “and it is absolutely critical to the Industrial IoT.”

PLM AS ‘DISRUPTIVE CAPABILITY’

Jean-Bernard Hentz has spent the better part of three decades “advancing intelligent design in manufacturing,” says the head of product life cycle management (PLM), research and technology, and innovation for Airbus. Today he is working to advance “disruptive PLM capabilities” within the scope of the company’s Advanced Digital Design and Manufacturing initiative.

Jonathan Riechert finds that visibility pays off in unexpected ways.

No stranger to the digital transformation, Hentz managed the PLM Research and Innovation processes for Airbus, which encompasses the company’s manufacturing IoT integration platform as well as agile development, advanced 3D visualization, model-based system engineering, big data and analytics. Among the proudest accomplishments with which he’s been involved was the development in 2005 of the manufacturing processes for the A380, the first Airbus model for which not only the aircraft itself but the full manufacturing processes were modelled in 3D.

“Today, with the IoT, we can follow the people involved and can check the full performance of the factory in 3D,” Hentz says. Further, centralized databases will soon be a thing of the past. The organization is moving to distributed data methodologies that allow the networks of companies that Airbus factories represent to “expose data among partners and to identify production risks earlier,” Hentz says. “It’s the only way to be flexible and efficient for the future, and the IIoT is helping make this possible.”

THE IoT AS SUSTAINABILITY ENABLER

Six years ago, when Lui Qiao left Toyota to join 3M Company, he had his work cut out for him. His mission? To lead the development of a technology platform, infrastructures, systems and processes that would enable the diverse materials science company to harness the promise of the Internet of Things through smart and connected products and solutions A major milestone since has been that launch of the company’s Electronics and Software Technology Platform, an important symbol of the start of 3M’s digitization era.

The IoT fits well with 3M’s “Science. Applied for Life” mission, says Qiao, who also established and serves as technical director of the company’s Software, Electronic and Mechanical Systems Laboratory. “Material science will be the fundamental for sustainable growth of our digital economy. The fusion and advancement of chemistry, physics, biology with mathematics and computational science will be the driving force to take digitization to the next level,” he says.

“The Internet of Things will change the way people think and the way we behave and act,” Qiao predicts. “Equipped with more data, information, know-how, knowledge, insight and foresight, we will better know ourselves and the outside world. More sustainable growth will be based on a new harmony of human life and the natural environment.”

A MINE FOR THE FUTURE

“Digital Codelco” is the Chilean national copper company’s vision for its mine of the future, one that through the application of automation and information technology sets a newIn the process, Orellana’s been inspired by the commitment of the company’s employees and the transformation of traditional miners into technological miners, along with a marked improvement in quality of life for the miners themselves, their families and the surrounding communities. “My dream is that the whole mining industry moves towards sustainable mining,” Orellana says. “In this dream, mining will become an engine for the development of our communities and countries, and a places for young talent to realize their innovative potential.”

“The mining business is in the midst of a digital transformation,” Orellana says. In 10 years, he expects all mine operations be intelligent, autonomous and tele-operated. “The big challenge will be to achieve virtuous collaboration between man and machine.” For instance, to develop proactive maintenance processes that will allow continuous mine operation, and the achievement of zero accident rates for both humans and machines.

Further, he anticipates that in 10 years, the company’s mines will be largely self-sufficient in water and energy use and that that company will successfully produce copper from deposits that today are infeasible—all in a sustainable and environmentally friendly way.

FEED THE WORLD WITH THE IOT

“The grand challenge of agriculture today is that by 2050 there will be 9 billion people on the planet,” says Lane Arthur. “How will we feed them all?”

Arthur found his passion for addressing the world’s food needs as a young technician with the U.S. Dept. of Agriculture. There, he learned of agriculture’s grand challenge, and found that he’s happiest when he’s contributing to its solution. Today, the PhD geneticist is director of John Deere’s information solutions group, and is uniquely positioned to help to solve world hunger through precision agriculture, much of which is facilitated through information gathered by the company’s farming equipment.

“We gather data not only about our machines themselves but about the work they do,” Arthur explains. “And as technology continues to advance, farmers will have increasing visibility and transparency into everything that happens on the farm.” The potential upside for more productive agriculture operations is enormous, but the farms of tomorrow will also require more sophistical agribusiness operators. Meanwhile, convincing today’s farmers of precision agriculture’s value can be a tough sell, but Arthur’s in it for the long term. “I’m very optimistic about the value it will bring.”

SMARTER ALUMINUM PROCESSING

As a 27-year veteran of the Alcoa Technical Center near Pittsburgh, Pa., Haresh Malkani has modeled, controlled and simulated most every of the operations involved in finishing aluminum—from rolling to casting to extrusion. Today, he leads the Alcoa Automation and Smart Manufacturing initiative, a global team focused on the development and deployment of advanced technical solutions across the company’s hybrid and discrete businesses.

“Phase I is all about information, its access, integration, visualization and contextualization across manufacturing processes—getting the right data in front of the right people in the right form.” Phase II—and the work that most excites Malkani—is about making these systems “intelligent on their own,” Malkani says.

As with many far-reaching technology initiatives, rallying a global team around a common mission proved a significant challenge, and one of which Malkani is most proud. “There was a lack of coordinated vision, broad sponsorship from leaders, and clear outline for the path forward. Getting them all together was my biggest accomplishment,” Malkani says.

“One of my dreams is self-aware, self-optimized manufacturing that is reactive, proactive and predictive,” Malkani says. To smooth the path forward, a clearer line of sight to the benefits is needed. “But transformation is coming, and it’s only a matter of time,” Malkani adds. “Small wins demonstrate value, then other investments are easier to justify. It’s a marathon, a journey of many small steps.”