Mature information is the key to smart transformation

By Edwin Elmendorp, information architect, Kinsmen Group

Digital transformation projects have been accelerating in the recent years. The advances in technology, such as industry 4.0 capabilities have enabled new ways of working. Even for the most reluctant companies, the global pandemic made them realize that now is not the time to stay behind. We all hear and see the daily overloads of how wonderful this technology is, but for many existing owner operators these advances feel far out of reach as they deal with older facilities and aging information. Maturity assessments can help shape an organizations digital agenda and drive initiatives forward.

What are maturity assessments?

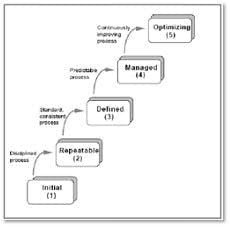

Maturity assessments are born from the belief that if your processes are well defined and executed, the result of that process is also of the desired quality. From this belief, academics defined the Capability Maturity Model (CMM).

The CMM describes a series of increasing capabilities that can be measured, as seen in Figure 1. Let us translate this to the world of Engineering Information Management and take the simple example of assigning new equipment numbers for a project that is executed in the facility.

A process at the initial level (see Figure 1) would for example describe that the organization is not even aware of the need for a process. The result of this is that equipment numbers are assigned at free will by either an EPC contractor or the engineer that might be working on the project. As a result, there is a duplication of numbers, no consistency, and no alignment between the different systems that use this information. The result of this is that it becomes difficult to find information, establish if the information is accurate. The bottom line is that people do not trust the information and often do a field-check to make sure what they have is accurate.

Figure 1

Let us then look at the opposite, a process description at the optimizing level would for example describe that a software solution controls the assignment of equipment numbers, there is a procedure that describes this, and the system is aligned with industry standards. As a result, information is accurate, unique, consistent, concise, clear, aligned and integrated across systems.

This was only one example and established maturity models can have hundreds of these types of indicators. We should not just think about the systems, but also how these systems are managed, how the processes are defined, how people are trained in these systems, how the company assigns budgets, how the initiative is supported, how strategies are set up, and much more. The input gathered for such an assessment is across various stakeholders in the organization. For each indicator, every participant then selects a rating (initial, repeatable, etc.) for how the company is performing. This then builds thousands of data points that can reveal underlying barriers for the management of information. This in turn can build a roadmap on how a company can improve.

Mature information management the key to digital transformation

Recent research has evaluated the different stages that companies go through as part of their digital transformation projects. Based on the input of 92 manufacturing companies, 3 major stages are identified for which the first ones consists of vertical data integration, energy management, and product traceability. The vertical data integration along the Manufacturing Execution System (MES), allows the aggregation of data from the lowest level in the field up to the ERP system. Existing facilities are already challenged in this regard because of the many siloed systems that manage and store information. As a result, the equipment number we referred to earlier is manually entered in half a dozen systems with less than favorable results in terms of efficiency and information trust.

The cost of wrong data

It is obvious that incorrect or toxic data can have large consequences. There are many anecdotal stories how the wrong revision of a drawing caused serious issues. Surprisingly enough, very limited real research has been done to date with respect to engineering information and manufacturing organizations. Although the few studies available were limited in scope, they revealed numbers that show a large impact on the organization, below are some of these.

· Cost—10% of the Operating budget; from a recent study in 2019, it was concluded that up to 10% of an annual operating budget could be lost because of poor engineering information. Many variables are used and depending on the specific situation these numbers will vary a lot.

· Cost—1.5% of annual revenue—from research performed by ARC Advisory group it was concluded that the cost of poor asset information can be upwards of 1.5% of annual revenue for an organization. Throughout their study, these numbers have been validated against other known studies to contrast and compare and validate the outcome of the study.

· Cost—$15.8 billion per year—from a well-known report produced by the National Institute of Standards and Technologies, it was estimated that the inadequate interoperability of information is costing the capital facility industry a staggering amount yearly. Although this study was performed in 2004, reviewing some of the more recent research shown above the presented number still seems relevant.

Maturity assessments can be a great tool to help a company advance on their digital agenda and they can help uncover hidden inefficiencies that can help a company take leaps forward.