By Danning Zhang, PhD, head of material characterization and Dr.-Ing. Natalie Rudolph is director of material & process development with AREVO

Additive manufacturing (AM), often referred to as 3D printing, is increasingly used for prototyping and rapid tooling. The versatility of the numerous technologies allows for fabrication of complex shapes and intricate internal geometries with the potential of significantly reduced cost due to mold-less manufacturing and reduced material waste. These technologies can create functional prototypes or colorful show pieces. Some end-use parts are used short term and others for extended period of times. Therefore, no one technology, be it plastic or metal, can be used universally.

And when it comes to functional end-use parts for extended use, the number of viable AM technologies is very limited, which further reduces the number of available materials and the associated design freedom.

Due to the intrinsically limited mechanical performance of printed neat-polymer parts, more and more composite-printing projects emerge. This trend was observed decades ago, when plastic-part manufacturers started to focus on fiber-reinforced polymer grades rather than neat polymer due to their improved shrinkage and mechanical behavior. Now, more than 70% of all plastic parts are manufactured using a composite material.

While the addition of short fibers increases the stiffness and (to a lesser extent the strength) of components, the highest performance comparable to metal parts can only be reached with continuous fiber-reinforcement. Therefore, additive manufacturing of continuous carbon fiber composites has gained interest in recent years.

A comprehensive review of all AM technologies using particle and fiber-filled composite systems was published by Wang et al. in Composites Part A in 2017. They conclude that AM parts from processes such as material extrusion, vat photopolymerization, direct write and powder-bed fusion can all be filled with micro and nano particles for functionalization. These added functions/enhancements are due to improved electrical and thermal conductivity, reduced shrinkage and warpage or added magnetic properties. The research work on fiber-reinforced polymers shows that only direct write and material-extrusion processes have been used so far. They did not include sheet-lamination processes in their overview. A more recent review from 2018 focused exclusively on fiber-filled material-extrusion printing was published by Brenken et al

Both papers list various research results on short-fiber-reinforced plastics that are mostly used for tooling due to their limitation in interlayer bonding strength. Furthermore, they present a comparison of tensile modulus and tensile strength for commercial and research systems using continuous fiber reinforcement. All data is reported in fiber direction only, which indicates that the strength perpendicular to it is very weak.

The sheet-lamination process has been omitted altogether, because of the lack of comparability due to their random fiber orientation and a lack of published research studies. It becomes evident that the low-fiber-volume content, as well as poor impregnation in the produced sample coupons, limits the mechanical performance already in fiber direction compared to conventional composites used in aerospace and automotive applications. Wang et al. conclude that “although the mechanical properties of composites were largely improved compared with pure polymer, the improvement was still lower than the theoretical value calculated by the rule of mixture.”

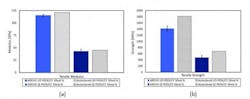

The following graphs show the research summary published by Brenken et al., and was extended with tensile data from the AREVO DED process, which were tested in a certified third party lab. (Figure 1 and Figure 2).

Figure 1 Tensile modulus comparison of different research results published for 3D printing of continuous fiber composites and the AREVO process

Figure 2 Tensile strength comparison of different research results published for 3D printing of continuous fiber composites and the AREVO process

It is seen that the AREVO DED process allows high-fiber content in the composite materials, and achieved about three times both the modulus and strength of those from other materials and processes. If the strength is plotted by category of process used regardless of the materials and fiber content (Figure 3), the variability of the data becomes evident. Even so, some of these data points are obtained using exactly the same material and process, the reported performance varies greatly. These variations are a major drawback for standardization and even certification of end-use products. As this graph shows, the AREVO DED process stands out again with much higher performance, which has been proven repeatedly in coupon and structural element tests.

Figure 3 Tensile strength comparison of different processes with the research results published for 3D printing of continuous fiber composites and the AREVO process

How did our process overcome the problem of mechanical performance and manufacturing capability?

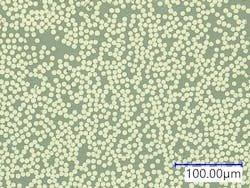

First of all, the AREVO process starts with a superior quality filament with high-fiber content, homogeneous distribution of fibers, and low-void content (<2%) (Figure 4), which guarantees high modulus and strength.

Figure 4 A closer look at the microstructure of the AREVO filament with 50 vol% CF, revealing homogeneous fiber distribution and low void content

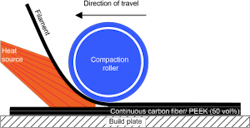

Then, in the deposition process, instead of a heated nozzle that is typically used in the material-extrusion processes, a laser is adopted to provide rapid heating, which makes it a Direct Energy Deposition (DED) process. A compaction roller compresses the filaments with sufficient pressure to eliminate the voids inside and in between layers, and consolidates the parts in-situ. Detailed studies of the characteristic control of the deposition system were conducted to tailor the optimum process parameters for any given material and geometrical features, to obtain good interlayer adhesion and consolidation. This moves the technology from prototyping to manufacturing.

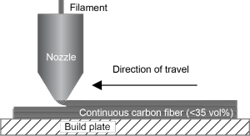

The following schematics in provide a visual comparison between the two general process types, as well as an overview of the advantages and disadvantages.

AREVO’s DED process

• High fiber volume content • Homogeneous fiber distribution • Maximal fiber alignment • Void content < 1%

Material Extrusion (FDM) processes

• Low fiber volume contents • Less than 30% of performance compared to traditional composites w¬ith same fiber content • Fiber breakage and misalignment • Void contents > 2%

With the AREVO system, a much higher strength is achieved, which can be seen by comparing Brenken’s and AREVO’s data in Figure 1 and Figure 2. It is the only process that eradicates all the defects from the material and the processing, such as voids, resin rich areas, insufficient compaction, degree of cure (for thermosets only). All of these issues have a detrimental effect on the mechanical performance of the components. Therefore, autoclaved composite parts show the highest strength and stiffness.

The blue bars in Figure 6 show the tensile properties of AREVO’s process compared to the same material and fiber content processed in an autoclave. The tensile modulus for both the unidirectional (UD) and quasi-isotropic (QI) materials are comparable to the autoclaved. The tensile strength of UD and QI materials achieved 80% and 70% of those of the autoclaved parts, respectively. This is even better than most out-of-autoclave (OOA) composite materials, which typically achieve less than 70% of the autoclaved strength.

Figure 6 (a)Tensile modulus and (b) strength of AREVO unidirectional (UD) and quasi-isotrpic (QI) materials compared to autoclaved aerospace grade materials (both 50 vol% CF)

With the excellent material properties, the AREVO DED process combines the advantages of additive manufacturing such as bridging (without support structure), overhangs and (in particular) load path optimized fiber path, with in-situ consolidation of high performance lightweight composite structures, without additional post-consolidation or curing. This provides tremendous benefits for the manufacturing of a large variety of engineering structural parts and, finally, brings the value of AM to manufacturing at scale.