Sharing is caring: Webinar covers how pooled data amps up performance

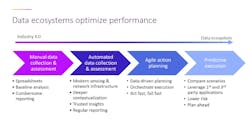

With manufacturing well into Industry 4.0, characterized by automation and employment of “smart” machines and factories, the next logical step for any company or public entity is to figure out ways to safely and strategically share their data to create productive ecosystems.

Data sharing has almost become necessary for business these days—and presenter Greg Le Blanc of Aveva, the global industrial software and IT consulting company, walked attendees through some processes and notable corporate examples of how to accomplish this safely and productively on Oct. 2 during the first of Smart Industry’s Fall Insight Series of webinars this week. The webinar was sponsored by Advanced Technology Services, Seeq Corp. and GE Digital. A recording of the webinar—as well as the others in the series—is available now. SI Editor-in-Chief Robert Schoenberger moderated.

Next up: Extend The Life Of Your Legacy Equipment With Condition Monitoring

“We’re on kind of a technological road to making different kinds of decisions, with a lot more help, requiring a larger ecosystem, because we can’t do it all ourselves,” Le Blanc said during the webinar, prefacing his conversation. Le Blanc and his group work with customers, users, partners, and internal resources to gather requirements and feedback to build the Aveva Industrial Platform data services. They help manufacturers share their process data with service providers to boost productivity and cut costs while keeping that data secure. A recent study by Forrester estimates that more than 70% of global data and analytics decision-makers are already expanding their ability to use external data, while another 17% plan to in the next year.

Midweek: Surf Loch Catches the Wave with Siemens Xcelerator to Deliver Custom Surfing Experiences

Henn, for example, created a system to send information directly from their production machinery to their internal data analysts and their external supply chain in the cloud. This allowed Henn to “unlock new business intelligence, improve component quality and reduce failure rates,” according to Le Blanc’s presentation. As another example, REG, a centrifuge maker, and Allied Reliability, a monitoring service, worked “to share real-time performance data securely using Aveva’s Data Hub, enabling proactive maintenance and reducing downtime.”

The Oct. 2 webinar challenged attendees to find ways to innovate, collaborate and operate faster with an enterprise-wide strategy, while maintaining maximum security and control; covered the challenges and opportunities with uniting different industrial elements, with tips to ensure measurable and scalable ROI; and educated them on how smart industrial enterprise is evolving, including the selection of real-world use cases from Henn, REG, and First Quantum Minerals.

About the Author

Scott Achelpohl

Head of Content

I've come to Smart Industry after stints in business-to-business journalism covering U.S. trucking and transportation for FleetOwner, a sister website and magazine of SI’s at Endeavor Business Media, and branches of the U.S. military for Navy League of the United States. I'm a graduate of the University of Kansas and the William Allen White School of Journalism with many years of media experience inside and outside B2B journalism. I'm a wordsmith by nature, and I edit Smart Industry and report and write all kinds of news and interactive media on the digital transformation of manufacturing.